ZE-Motor (Zero Emission Motor)

Since the 1960s, Sintertechnik has been pioneering the development and manufacturing of customized solutions designed to reduce electromagnetic noise and extend the service life of small motors. For over 40 years, these components have been trusted by global leaders in drive technology for their series production, proving their reliability even in the most extreme conditions, such as on planet Mars, as well as in the automotive industry, aircraft, and medical devices. In addition to significantly lowering electromagnetic noise emissions, Sintertechnik products can also enhance the motor lifespan, often by a factor of 10 or more.

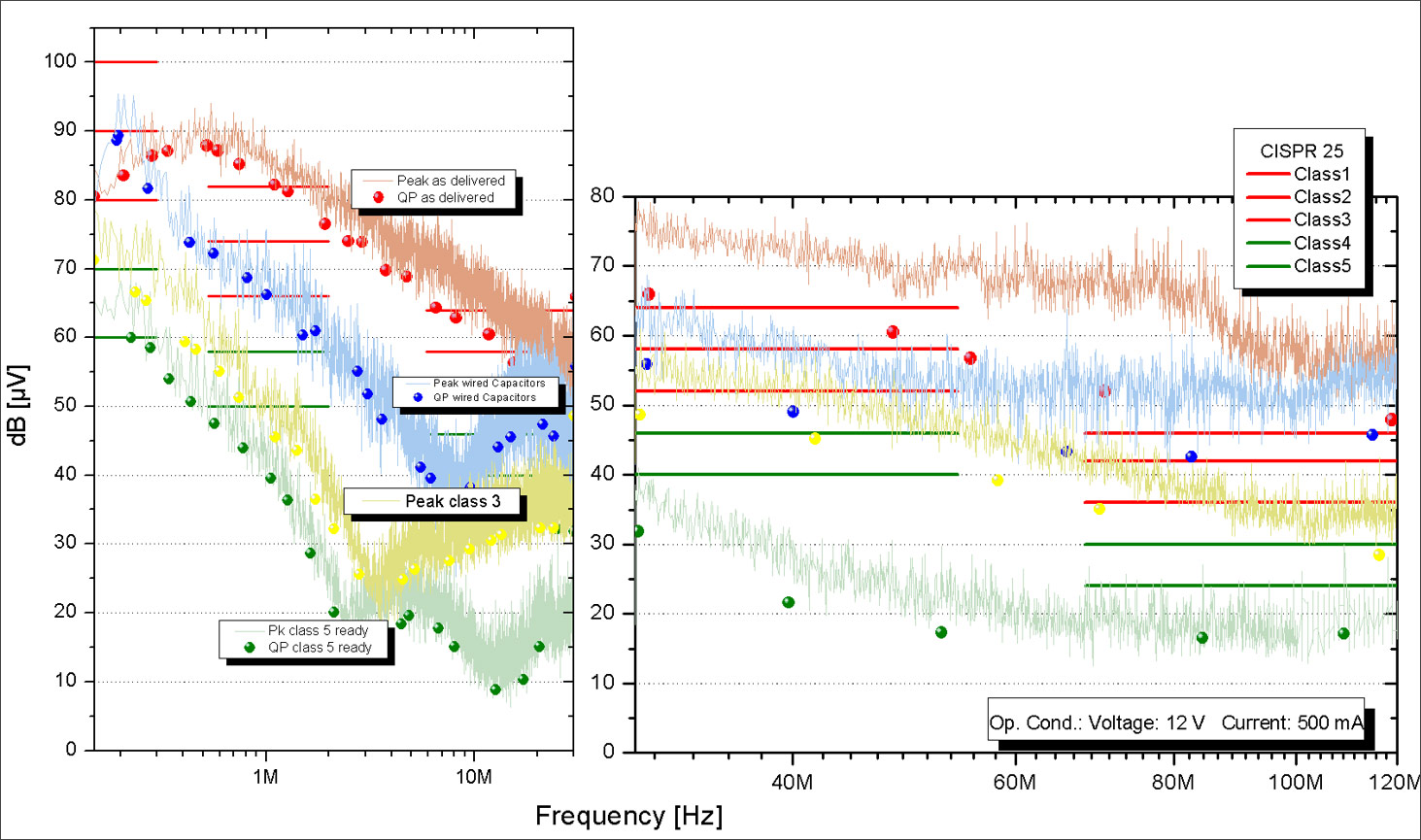

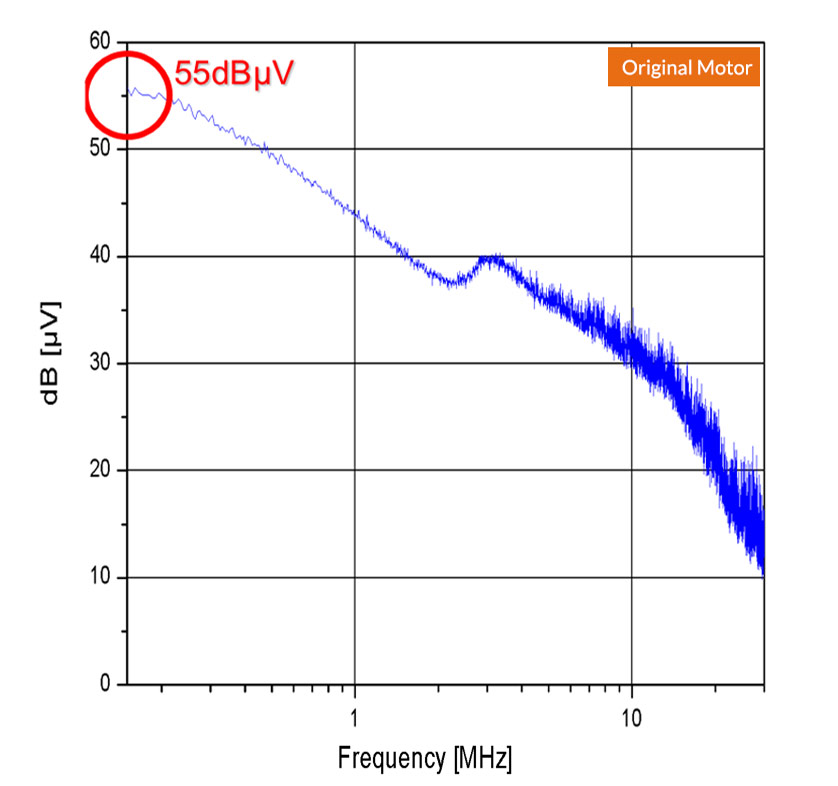

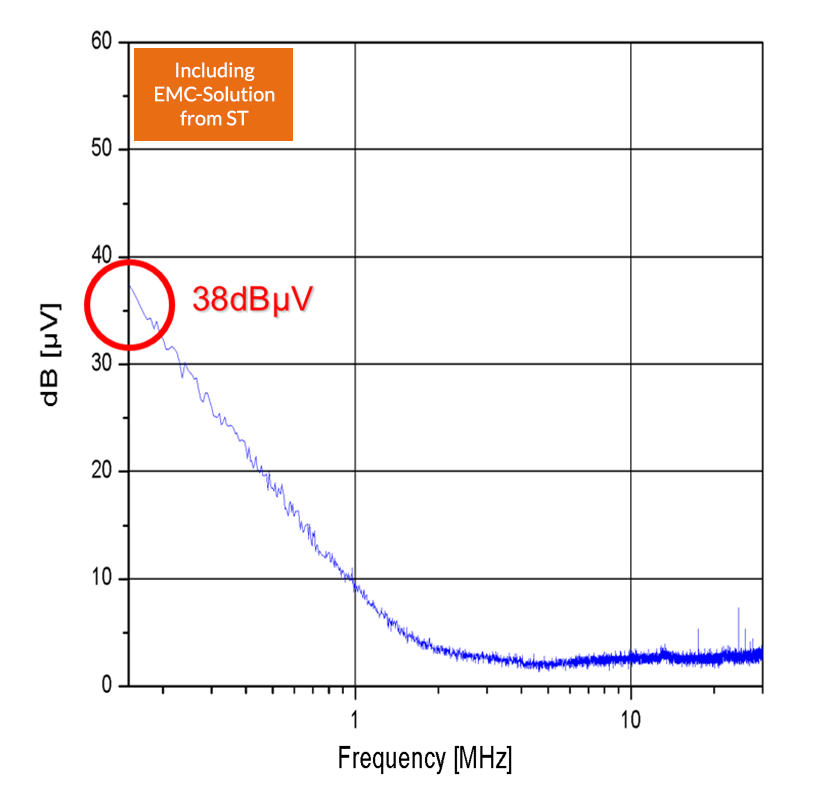

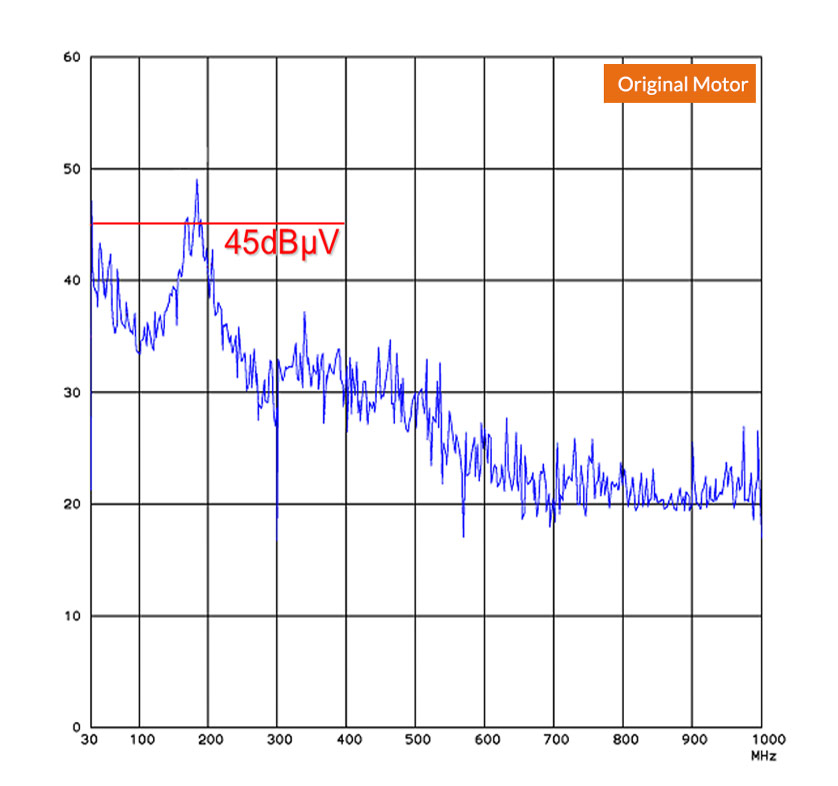

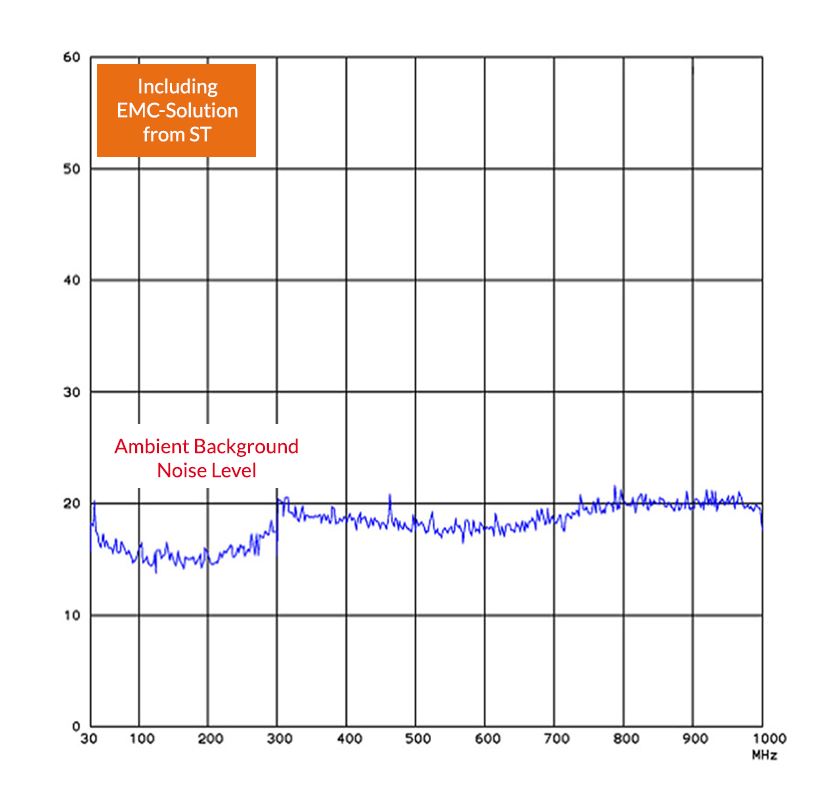

Example for a successful development of an optimised EMC-solution for a motor used in medical technologies

MOVE ARROWS BELOW

At high frequencies, a reduction down to the atmospheric background noise level is achieved

MOVE ARROWS BELOW

Devices for EMC improvement and extension of service life of electric motors

The growing use of small motors in our everyday devices (e.g. electric windows, sunroofs in cars, hairdryers, printers, electric toothbrushes, computers, medical devices and industrial automation’s, etc.) is leading to increasing interference between electronic devices, caused by electromagnetic emissions of the motors itself often referred to as “electrosmog.” This situation will become considerably worse in the future as the conductor track density of microprocessors continues to increase and leading to heightened sensitivity to such disruptions. To address this growing concern, the Electromagnetic Compatibility (EMC) Law was introduced in 1996 already. This law mandates that the functioning of any electronic device, including electric motors, must not interfere with the operation of other electronic devices. This regulation is reflected in standards like CISPR25, which has evolved over time. The earlier version covered a frequency range from 150kHz to 108MHz. However, the updated CISPR25:2021 now defines a significantly broader range, extending from 150kHz to 5,925MHz. This is highlighting the growing need for effective EMC solutions.

Since the 1960s, Sintertechnik has been pioneering the development and manufacturing of customized solutions designed to reduce electromagnetic noise and extend the service life of small motors. For over 40 years, these components have been trusted by global leaders in drive technology for their series production, proving their reliability even in the most extreme conditions, such as on planet Mars, as well as in the automotive industry, aircraft, and medical devices. In addition to significantly lowering electromagnetic noise emissions, Sintertechnik products can also enhance motor longevity, often by a factor of 10 or more.

Every motor presents unique challenges when it comes to electromagnetic noise suppression. We offer a collection of case studies upon request, showcasing motors across different power classes that have successfully reduced electromagnetic emissions. At Sintertechnik, we are ready to collaborate with you to develop and produce the ideal EMC solution for your motor, ensuring optimal performance and compliance.