Since the 1960s, Sintertechnik has been pioneering the development and manufacturing of customized solutions designed to reduce electromagnetic noise and extend the service life of small motors. For over 40 years, these components have been trusted by global leaders in drive technology for their series production, proving their reliability even in the most extreme conditions, such as on planet Mars, as well as in the automotive industry, aircraft, and medical devices. In addition to significantly lowering electromagnetic noise emissions, Sintertechnik products can also enhance motor lifespan, often by a factor of 10 or more.

Iron core motor with mechanical commutation with an enormously extended lifespan

The effects of climate change are massively driving energy transition efforts worldwide, accompanied by a switch to electrical energy supply. The rapid transition from combustion engines to electric mobility is an impressive evidence of this change. Consequently, electric drive development is becoming more and more important, while their optimization in all performance areas is an integral part of current advances in this field. Further challenges include the sustainable use of resources, which means that extending the lifespan of products and components is becoming increasingly important. And last but by no means least, the importance of the increasing electromagnetic sensitivity of electronic products and components (EMC compatibility), arising from, among other things, and the increasingly density of conductor path structures on microchips that surround us in all areas of our everyday life. The fact that this increased electromagnetic sensitivity is being taken into account by the legislature is shown in the revision, for example, of the standard CISPR25:2021 (Vehicles, boats and devices powered by internal combustion engines – radio interference characteristics – limit values and measurement methods for the protection of on-board receivers). The upper limit frequency has been significantly expanded to 5,950MHz in the latest version. Over and above these requirements is the demand for cost reductions, especially in the automotive sector, in order to persevere in the ever-increasing competitive pressure worldwide; not just in the area of electromobility.

With decades of experience in the area of radio interference suppression (EMC – Electromagnetic Compatibility) in small electric motors, particularly in extending the service life of high-end ironless motors, Sintertechnik supplies the world market leaders with appropriate and effective solutions. It is not without reason that the Mars rover “Sojourner”, the first wheel-driven vehicle ever to travel to another planet, was equipped with motors whose service life could be significantly extended with a Sintertechnik solution. Sintertechnik components contributed substantially to the success of the first mission to Mars, as the mission was significantly extended many times over its originally planned duration.

Based on all these requirements and demands, Sintertechnik was instructed to find solutions for two related tasks pertaining to applications in the automotive sector. Both objectives were aimed to replace two expensive motors by cost-effective, easy-to-control, mechanically commutated DC motors. Firstly, a stepper motor in a flap adjustment (HVAC) was to be substituted, and secondly, the complex control of an electronically commutated BLDC-motor was significantly simplified for a specific application in a pump.

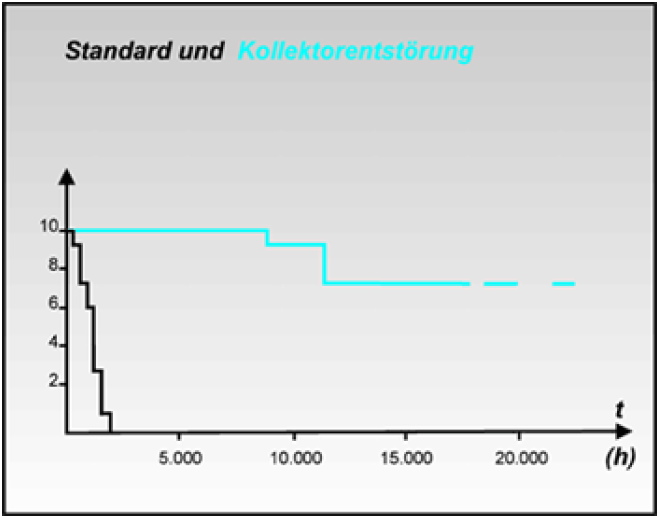

Due to the demanding requirements of both applications, such as low noise, low starting voltage, no contamination (e.g. abrasion), high efficiency, low electromagnetic emissions (EMC) and long service life, a motor with precious metal brush commutation (PMB) was chosen. The applications in the automotive sector ruled out the use of an ironless motor for cost reasons from the very start. Ultimately, a particularly cost-effective iron core motor with PMB commutation and 12V operating voltage was chosen from the standard range of a renowned motor manufacturer. This motor is used in large amounts worldwide in a wide range of applications (including automotive) and already has a high level of quality as a standard. The current version of this motor has a service life of just under 900 hours and approximately 200,000 rotation-direction changes (CW/CCW). However, the client’s target requirements for this PMB-commutated motor were a service life of around 4,500 hours, equating to at least 1 million CW/CCW cycles.

Sintertechnik commenced on the development of solutions in close collaboration with the motor manufacturer. After extensive preliminary testing, the resulting improvement-adaptations were implemented and evaluated. The results of long time testing is that these motor modifications have already exceeded a service life of far more than 10,000 hours, as well as more than 3 million CW/CCW cycles under load under normal conditions. This has exceeded the client’s original target (1 million CW/CCW cycles, 4,500 hours) by far. As a side-effect it was found out, that the motors are showing a reduced acoustic noise level, compared with the standard version of the motor. The enormous increase of the service life is opening the possibilities for a significant expansion of the current range of applications for this motor. Also, it can be implemented as a cost-effective replacement for significantly more expensive motors in this power class.

In view of various requirements for other applications by the clients, the motor and the Sintertechnik method for extending its service life have now been further developed and adapted to operating voltages of 24V, 36V and 48V. Operating voltages that deviate from these can also be made according to specific customer requirements; subject to appropriate quantities. For EMC-critical applications, these and similar motors can be modified in cooperation with the customer and in accordance with the stipulated requirements in regards to electromagnetic noise suppression (e.g. in accordance with Class 5 of the CISPR25:2021 standard).

The motors can also be supplied with special gearboxes on request and in co-operation with the customer. Application-specific complete actuator systems can be developed and supplied. Due to the existing production lines for the low-cost basic version of this motor at the motor manufacturer, the motor is not only suitable for small, but also for medium to large series up to several million p.a. Projects for motors of a similar size can be realised in cooperation with the customer on request.